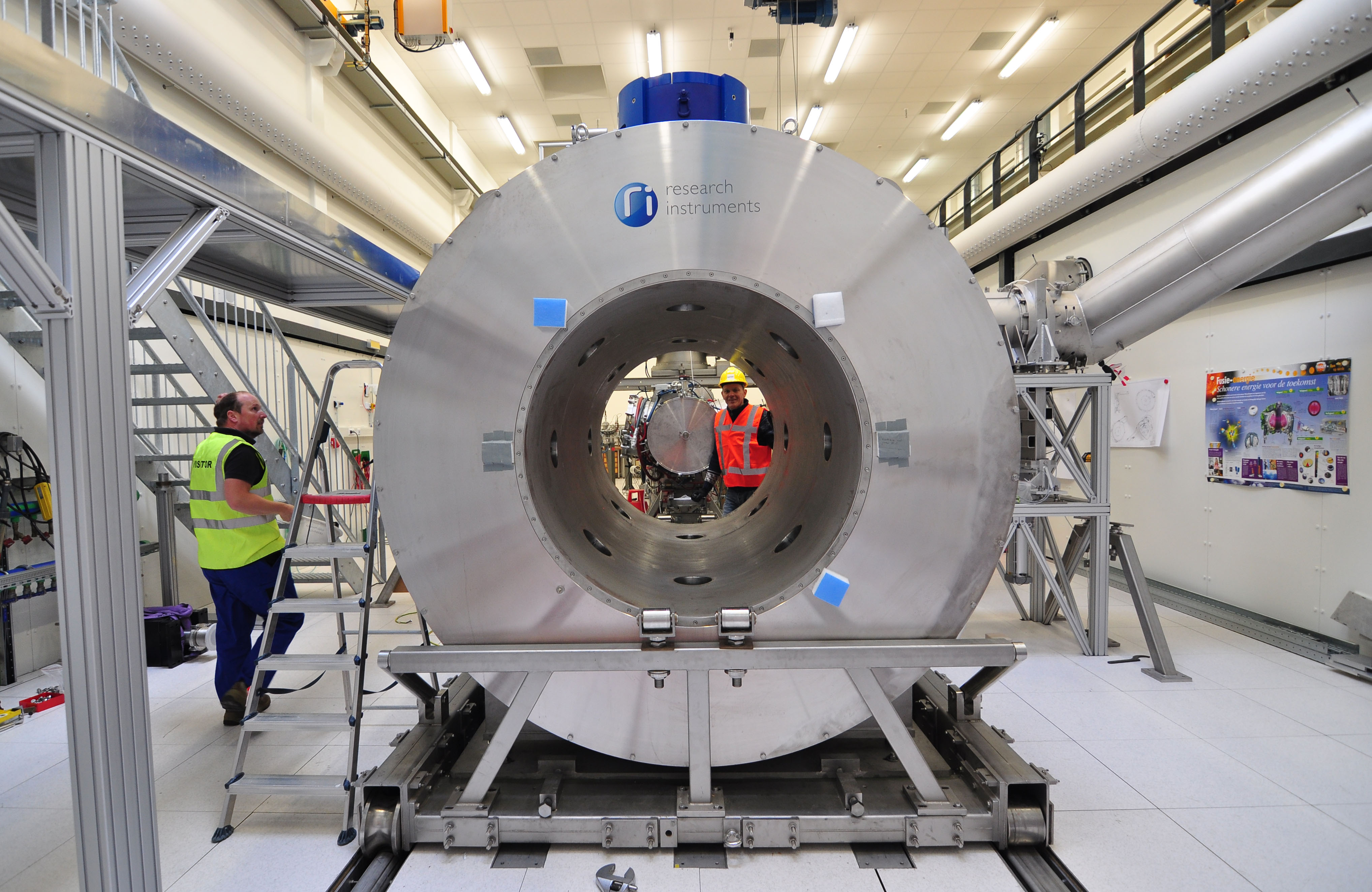

With the installation of a superconducting magnet on its unique facility Magnum-PSI, DIFFER can now study the long-term behaviour of materials under the harsh conditions in future fusion reactors. On Saturday 8 October, the 17 ton magnet arrived at DIFFER and was carefully lifted onto its chassis by a 400 ton crane. This system will enable record plasma exposures in our facility for plasma-wall interactions under fusion reactor conditions.

At 4 AM on a Saturday, the university campus around DIFFER in Eindhoven is usually very, very quiet. Not this morning. The Magnum-PSI team led by Hans van Eck is on site to receive their long-awaited superconducting magnet. Starting at manufacturer Research Instruments in Bergisch Gladbach (D), the magnet on its low loader truck has driven throughout the night to arrive at its final destination. Shortly after the magnet, trucks arrive carrying the large crane which will lift the magnet into place.

The purpose of Magnum-PSI is to investigate if materials can cope with the extreme circumstances in a fusion reactor, a sustainable energy system producing clean electricity from the same process which powers the sun.

The 2.5 tesla superconducting magnet is the cap stone for the Magnum-PSI facility, explains project leader Hans van Eck. The magnetic field it produces takes the hot, charged particles in the plasma from Magnum-PSI's cascaded arc source, and guides them to the target material in a tight energetic beam. This replicates the conditions at the wall of a fusion reactor, where materials will face intense bombardments of heat and fast particles similar to those at the surface of the sun.

Van Eck: "With Magnum-PSI, we have the only experiment in the world which can replicate the plasma conditions in a future fusion reactor like ITER in a laboratory setting." With the previous pulsed magnet system, Magnum-PSI could only maintain those conditions for 10 to 20 seconds at a time, after which the copper coils needed to be cooled for 20 minutes. "The superconducting magnet, we can leave on for a much longer time, even longer time than a plasma shot in ITER. We can now really explore how materials evolve during their entire lifetime in ITER - we can simulate that in the span of a couple of months."

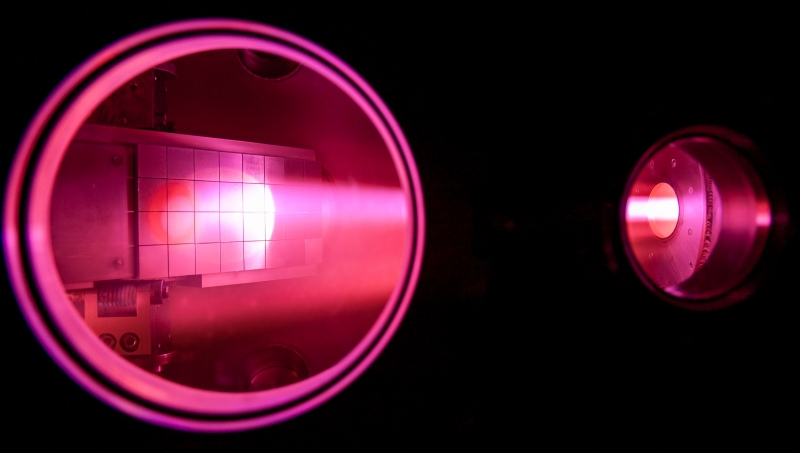

Left: the ITER tokamak is the first of its kind designed to prove the technical feasibility of fusion as an energy source. Right: tungsten monoblocks for the ITER exhaust (divertor) were exposed to the Magnum-PSI plasma beam at the experiment's original Rijnhuizen site.

At the exhaust of the ITER fusion reactor, materials will face particle fluxes of 1023 to 1025 particles per square meter every second. The heat load is 10 MW per square meter, up to 1000 MW per square meter during sudden energy bursts from the fusion plasma. Magnum-PSI is the only laboratory experiment in the world capable of exposing materials to those intense conditions. In previous experiments, Magnum-PSI already tested components from ITER and other fusion experiments.

Custom design with 16 viewing ports

The superconducting magnet's requirements went beyond merely confining the plasma into a tight beam, Van Eck explains. "We want to do the first experiments where you can investigate the long-term effects of exposing a material to fusion plasmas." That meant a superconducting system, which can maintain its magnetic field for hours on end. Proper access for diagnostic equipment to monitor the plasma was also a requirement. "We designed the magnet with a large central bore of 1.25m to fit the vacuum vessel of Magnum-PSI into, and with viewing ports straight through the magnet's cryostat", Hans van Eck points out. These 16 radial ports make it possible to determine, for instance, the plasma temperature and density by shooting lasers through the plasma.

provide ample access for diagnostics.

Factory tests

The large number of viewing ports in the magnet also mean additional welds in the cryostat, which makes it harder to keep the liquid helium-cooled superconductor isolated from the room temperature environment. Factory tests in 2011 showed a faulty electrical connection, after which parts of the magnet were rewound and welds strengthened. In recent tests, the entire system was checked: the capacity of the cooling system, the system's helium usage, the shape and smoothness of the magnetic field - everything checked out. The superconducting magnet was ready for transport.

Lifting the Magnum-PSI superconducting magnet from its truck and over the DIFFER building.

Smooth flight

Saturday morning, 8 October: on the Eindhoven campus, the 400 ton crane with its 50 meter arm has been assembled. Its mass and length will be necessary for this operation. The crane needs to hoist the magnet from the road and swing it across to the centre of the DIFFER building. It is 8:30 when the massive crane rights itself and the truck carrying the superconducting magnet drives into position. After securing the magnet to the crane's yoke, 17 tons of stainless steel and superconductor slowly rise off the supporting truck.

Lowering the superconducting magnet into the Magnum-PSI experiment hall.

Throughout the operation, the Magnum-PSI team monitors every movement. A smooth movement of the crane positions the magnet over the roof hatch into the Magnum-PSI hall; careful positioning and millimeter movements ease the system down onto its cradle. A read-out of the accelerometers shows that the magnet remained a factor 2 under its safety limit during the entire transport and lifting procedure. A round of congratulations, a quick look at the future, and operations wind down with the dismantling of the cranes.

Aligning the superconducting magnet before it is lowered onto the supporting chassis.

The road to Magnum-PSI operations

Starting Monday 10 October are the installation of the magnet’s auxiliary equipment and the first integration steps with Magnum-PSI. Over a three week period, the magnet will be cooled down to its operating temperature of 4.2 K. Once superconducting, a slow ramp of the current builds up the magnetic field so that tandem tests of the plasma source and magnet can commence. Marco de Baar, head of DIFFER's fusion energy research, expects that Magnum-PSI will be up and running again in January 2017. The first international partners are already knocking on the door to come experiment with wall materials for future fusion reactors.

superconducting magnet. Left to right: Jörg Zeutschel (Research Instruments),

Paul Smeets, Hans van Eck, Serge Brons, Miranda van den Berg,

Richard van de Sanden, Wim Koppers, Marc van de Pol, Ton Arends (DIFFER).

Go to the News page.