In order to win clean and sustainable energy from nuclear fusion, researchers need to protect the wall of their reactor against the hot plasma (ionised gas) in their artificial sun. PhD student Stein van Eden and his colleagues at DIFFER discovered that a thin layer of molten metal can dilute and disperse the plasma. This helps tackle the issue of the reactor wall's lifetime, one of the big obstacles of turning fusion into a power source. The researchers at the Dutch Institute for Fundamental Energy Research published their work in the top journal Physical Review Letters.

Self-Regulated Plasma Heat Flux Mitigation Due to Liquid Sn Vapor Shielding

G. G. van Eden, T. W. Morgan, D. U. B. Aussems, M. A. van den Berg, K. Bystrov, and M. C. M. van de Sanden

Phys. Rev. Lett. 116, 135002 - website / pdf

Youtube: front view (left) and side view (right) of liquid tin in the hot plasma beam of DIFFER's experiment Pilot-PSI. The centre of the target heats up and cools down in cycles. The researchers believe that this is the 'self-regulated heat flux mitigation': heating of the plasma leads to more evaporation. This consequently cools down the plasma, leading to a mitigated heat flux to the surface. As the surface cools, evaporation diminishes and the plasma heats the surface again, repeating the cycle.

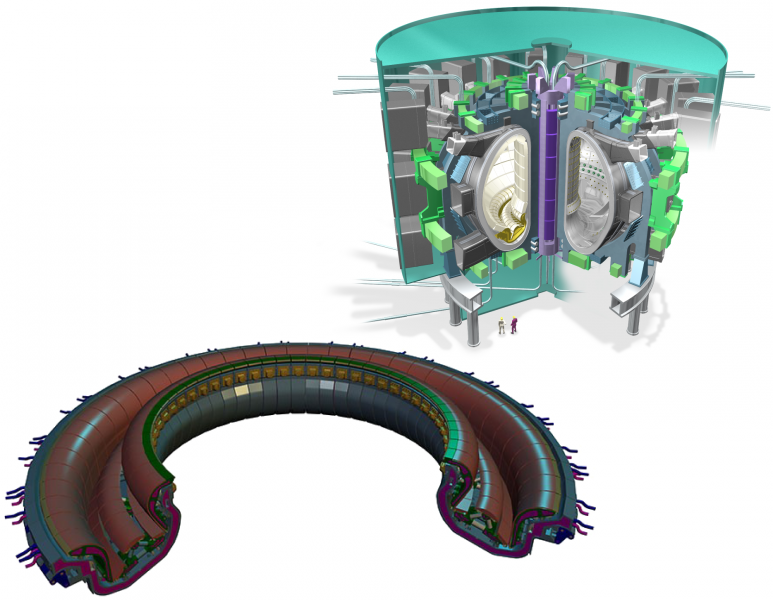

One of the main challenges on the road to fusion energy is to find a material that can withstand the extreme plasma conditions near the reactor exhaust or divertor. In the future fusion reactor ITER, the divertor will face a continuous particle bombardment and a heat flux of ten megawatt per square meter. Physicist Stein van Eden: "Those conditions are comparable to the surface of the sun or a rocket exhaust."

Together with his colleagues at the DIFFER institute for fundamental energy research, Van Eden is searching for even more robust options than the current fusion reactor wall materials. Instead of a wall of solid heat resistent tungsten, the team are investigating a self-healing flow of liquid metal running over the reactor wall.

Unexpected self-protection

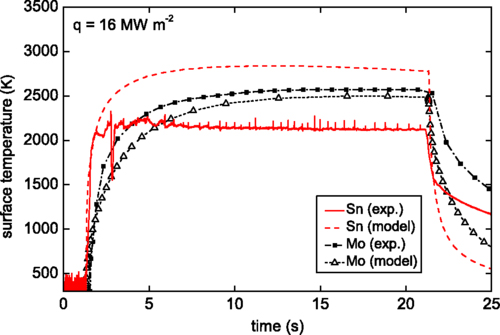

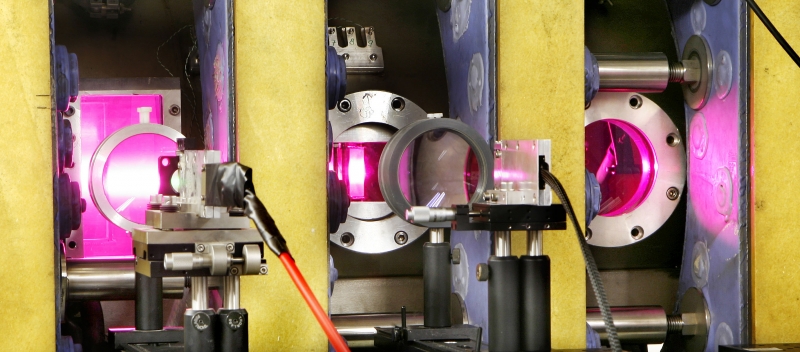

Van Eden: "Our laboratory facilities Pilot-PSI and Magnum-PSI are the only ones in the world that are able to expose materials to the extreme conditions at the wall of a fusion reactor." In his experiments in the Pilot-PSI facility, he ran a layer of liquid tin over a sponge-like tungsten holder. "When we exposed the liquid to reactor-like plasmas, we saw that the temperature stayed much lower than when we used a solid wall. Somehow, the liquid wall can cool itself."

The big question: where did the energy go? Van Eden: "Above our liquid layer a vapour cloud develops, which can catch the energy from the plasma and radiate it to all sides. This process of vapour shielding ensures that the energy is dispersed over a much larger area than when the plasma would strike the wall directly. It is also self-regulating: the more heat, the more vapour, which consequently cools the surface again."

Group leader Thomas Morgan (DIFFER): "In an experiment such as ITER, damage to the wall would mean loss of experimental time. In a blueprint fusion power plant like ITER's successor DEMO, a months-long repair time is out of the question. This makes the concept of a self-repairing, self-shielding reactor wall covered with liquid metal enormously attractive."

The road to fusion energy: ITER and DEMO

The international fusion reactor ITER is being built to prove the technical feasibility of fusion energy. ITER will start up around 2025 and is designed to be the first fusion experiment to generate more power from fusion (500 megawatts) than is needed to stabilise the reaction (50 megawatts). The fusion reaction will bombard the ITER wall with a 10 megawatt per square meter bombardment of heat and fast particles. This hovers at the edge of what current materials can manage. After successful experiments in ITER, attention will shift to building the demonstration fusion power plant DEMO in the '30s and '40s. This reactor is planned to deliver between 1500 and 2000 megawatt of electrical power to the grid.

European collaboration in Horizon2020

Finding the right wall materials for a fusion reactor is one of the eight tasks of the European Horizon2020-programme EUROfusion. This programme contributes to the development of ITER and helps to design ITER's successor DEMO. As the national EUROfusion partner, DIFFER is helping Dutch researchers and companies to connect with the European fusion research.

Go to the News page.