In the journal Plasma Processes and Polymers, plasma researcher Sergey Starostin and his colleagues at Fujifilm Research and DIFFER demonstrate the viability of a new technique to deposit functional foils. These can be used as moisture resistant top layers for thin film PV cells, or for efficient gas separation in the context of sustainable fuel production. In their paper, the team describe how they can produce equal or better quality foils with an atmospheric pressure plasma deposition technique than in the standard PECVD low pressure operation. This can lead to functional foils production at much higher speed than is possible in current setups.

Towards Roll-to-Roll Deposition of High Quality Moisture Barrier Films on Polymers by Atmospheric Pressure Plasma Assisted Process, Starostin et.al., Plasma Processes and Polymers, DOI 10.1002 / ppap.201400194

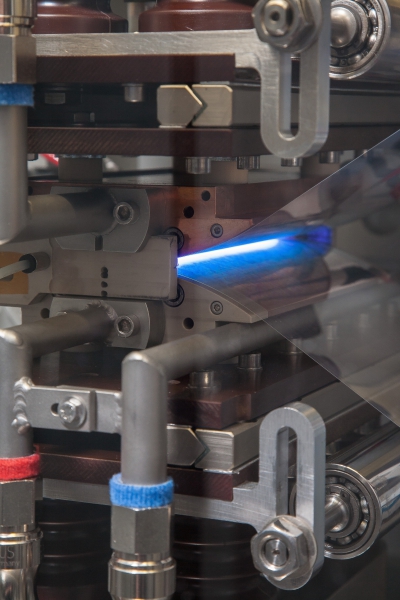

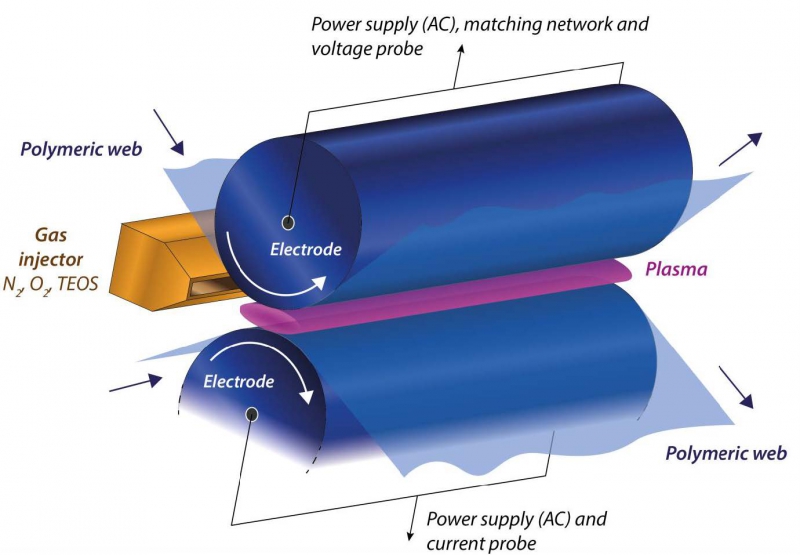

Atmosferic plasma layer deposition

Atmosferic plasma layer deposition

During plasma-enhanced chemical vapor deposition (PECVD) a thin layer of material is deposited on a substrate, in this case silica on a flexible foil. Use of the plasma phase (charged gas) allows for selective use of chemical pathways to deposit the desired layer. DIFFER and Fujifilm are now exploring the next step in this field: moving from low to atmospheric pressure for equal quality at higher throughput.

In their paper Sergey Starostin and his colleagues show that foils produced with the atmospheric pressure method can match or exceed those produced with the standard low pressure technique. Starostin: "This was really non-trivial! We needed to optimise the entire system for atmospheric pressure operation, starting from the design of the electrode to the realization of how much energy we need we need to deliver per precursor molecule to tailor the properties of the thin film."

credit: Marcel van de Kerkhof / green-plasma.eu

Moisture resistant layer for thin film PV cells

Fellow researcher Hindrik de Vries: "One important application of the silica layers that we are creating is as a moisture barrier film to protect thin film photovoltaic devices from degradation. A cost effective route to deposit good quality barrier films has not been developed and this research may provide a good solution to achieve this goal."

Large scale application

Jan Bouwstra, senior researcher at Fujifilm: "Functional foils are very interesting, but for large-scale application we need insights into and control over the skittish plasma during the deposition process." In other words: how do the plasma channels move over the substrate over time and how can this fickle process still result in a homogenous layer with well-defined growth speed, porosity and permeability? Bouwstra: "In this collaboration we are building the necessary knowledge base to introduce functional film technology in a cost-effective way at large scale."

Collaboration

This research is part of an Industrial Partnership Programme funded by FOM. Part of the research programme on atmospheric plasma deposition is funded by the EU programme LIFE+. Through this programme the EU subsidises a range of projects that are related to sustainability. Important objectives of LIFE+ are the dissemination of atmospheric plasma technology for the use in flexible solar cells and a more economical use of raw materials and energy. As a new enabling technology atmospheric plasma deposition may play an important role in achieving these goals.

Go to the News page.