Thanks to funding through the NWO Open Technology Programme the research project ‘Development of additively manufactured tungsten heat shields for nuclear fusion’ can start. This project will exploit the unique infrastructure that is developed between TU/e and DIFFER as part of the Liquid Metal Shield laboratory (LiMeS-lab).

The proposal ‘Development of additively manufactured tungsten heat shields for nuclear fusion’ for the Open Technology Programme (OTP) has been granted by NWO. Dr. ir. Hans van Dommelen (TU/e) and co-applicants Prof.dr.ir. Marc Geers (TU/e) and dr. Thomas Morgan (DIFFER) aim to make a significant contribution. Their research focuses on how to reduce the heat load on the reactor wall and ensure its durability.

LiMeS-lab

Fusion faces a major challenge to handle the extreme heat and particle loads that enter the exhaust of the reactor. The LiMeS-lab project provides a comprehensive suite of equipment to manufacture and test liquid metal plasma-facing component designs that can deal with these conditions. Morgan: “Liquid metals could be highly beneficial as a wall material because they will self-heal from damage or erosion by the plasma, and can strongly evaporate which shields the underlying solid components from damage and remove heat from the plasma by radiation and collisions.”

Advancements

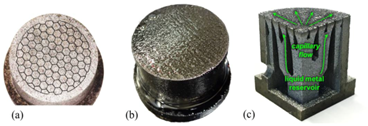

The new OTP project will provide funding for PhDs who will use this new infrastructure to advance these concepts. “In particular we aim to use additive manufacturing to create metal scaffolds that are shaped to hold the liquid metal in place on the wall. Using a new 3D metal printer which is specially adapted to process the high-melting point metals we want to use, like tungsten, we aim to do two things in this project in particular: firstly we will develop the print strategy to produce high quality, high resolution printed pieces, and characterize and optimize their microstructure. Secondly we will use this approach to produce optimal structures to confine the liquid metal in our scaffolds, and then test the performance of these structures under realistic loading conditions using our specially adapted linear plasma device, which is another part of the LiMeS-lab project”, explains Morgan.

Exciting opportunity

The OTP funding is an exciting opportunity because it is focused on collaborating with industry. Morgan: “We will work together with Philips Dunlee, who have extensive expertise in additive manufacturing of tungsten, and over 100 years of experience in working with tungsten. Together with colleagues from the Mechanical Engineering department of the TU/e who are experts in materials science, and DIFFER’s plasma and liquid metal expertise, we have a top team to work together towards new solutions.”

Six projects awarded

The Open Technology Programme provides funding for application-oriented technical-scientific research that is free and unrestricted and is not hindered by disciplinary boundaries. The programme offers companies and other organisations an accessible way to participate in scientific research that is intended to lead to societal and/or scientific impact. In total six projects in the NWO domain Applied and Engineering Sciences are awarded. NWO is contributing over 4 million euros to these application-oriented technical-scientific projects. Industry and other organisations add over 350,000 euros.

Read more on the NWO website (in English and Dutch).

Author: Rianne van Hoek

Go to the News page.