Green hydrogen as a means of storing electrical energy is the future. The new SCALE consortium headed by DIFFER will investigate a new approach to generate hydrogen. DIFFER, together with the TU/e and a number of other parties was recently awarded 1.25 M€ of funding by NWO for this new project to prepare the ground for the next generation of so-called AEM water electrolysers.

Water electrolysis is a means of producing green hydrogen by splitting water using renewable electrical energy. It has the potential to meet the domestic, mobility and industrial needs of green, cost-effective and sustainable hydrogen production for end-use and as an energy storage medium.

However, existing electrolysis technologies suffer from a number of drawbacks, explains DIFFER group leader Mihalis Tsampas. “Most importantly, current approaches are either using scarce and expensive materials and have limited compatibility with an intermittent electricity supply of renewables, such as wind or solar energy.”

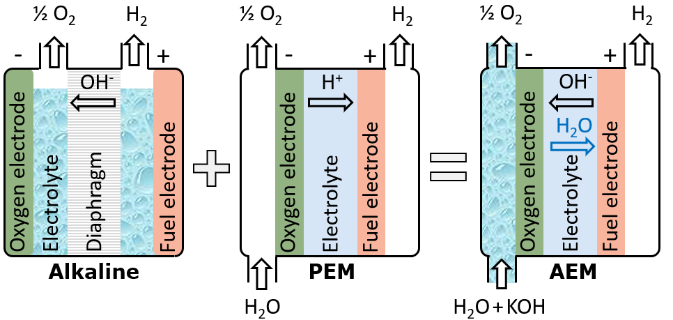

AEM (anion exchange membrane) electrolysers are an emerging solution to these issues with existing electrolysers. They promise to be suitable for intermittent supply and use cheap and abundant materials. Small scale AEM electrolysers are available for laboratory tests, but a lot of fundamental questions remain on design, materials and scale-up. Tsampas says: “The limitations of these systems under conditions closer to practice are still unknown. SCALE will investigate exactly that. Within DIFFER, we will focus on the design and development of novel electrode architectures and prototypes.”

Tuning properties

The Applied Physics department of the Eindhoven University of Technology (TU/e) has joined SCALE to provide expertise on electrocatalyst design and engineering, says Adriana Creatore. She is a specialist in the field of Atomic Layer Deposition (ALD) for energy technologies. With this technique, new electrocatalysts for water electrolysis can be synthesized at the atomic scale. “No other method offers so much freedom and control in tuning properties, such as chemical composition and morphology. Therefore, we can go beyond the design of catalysts and gain a fundamental insight in the activation mechanism.”

For Creatore, practical milestones such as a tenfold increase in current density (a measure for how much hydrogen an electrolyser can generate per surface area) are just as important as generating this fundamental knowledge.

Also project leader Tsampas never loses sight of the applicability. “Personally I am driven to find solutions for challenges in society. This project is a bridge between academic interest and society. If our results will be the beginning of a new project for future electrolysers by one of our partners, this would be great.”

Industrially relevant

One of these partners is ISPT, a non-profit organisation where Andreas ten Cate is the program director of the Hydrohub innovation program. Its MegaWatt Test Center hosts a 250 kW electrolyser test facility. Promising findings on electrodes and AEM electrolyser designs developed within SCALE may be tested here at industrially relevant conditions. “We are facilitating the cooperation between research institutes and relevant industrial partners,” says Ten Cate.

Ten Cate sees good opportunities for the AEM technology. “It is the next step in water electrolysis. However, AEM is not proven at large scale and for long operating times yet.” Ten Cate expects that the SCALE project will deliver new results and insights on AEM eletrolyser technology that is suitable for industrial partners to adopt and develop into a commercial product. “I believe there is a good chance that this will happen.”

Education and society

A third important component of SCALE is the promotion of education and the embedding of innovations in society. The Technology, Innovation and Society group at TU/e and the Fontys University of Technology are involved in this. Creatore says: “This form of collaboration between physics, engineering and social science is new to us and it will be challenging. But in the end, it will be rewarding as well.”

Project consortium

Academic partners of SCALE are DIFFER, TU/e and FONTYS. Co-funders are ISPT, Syngaschem BV, VSPARTICLE and Veco Precision. Toyota Motor Europe and FORTH institute are international cooperation partners.

More information

Dr. Mihalis Tsampas, head of the DIFFER research group Catalytic and Electrochemical Processes for Energy Applications (CEPEA).

The NWO NWA programme "Electrochemical Conversion and Materials" (ECCM).

Go to the News page.