DIFFER has reached an important milestone: the linear plasma generator of Upgraded Pilot-PSI (UPP) is operational again with greatly improved features. The machine is used to test materials to be used under the harsh conditions in fusion reactors. “Although test results are still preliminary, we are confident that we have improved the performance of the linear plasma generator by at least an order of magnitude”, says research engineer Marc van de Pol.

For Marc van de Pol, UPP has been the most important project in recent years. He has been working for DIFFER for a long time. After graduating as an electrical engineer from Eindhoven University of Technology, he came to Rijnhuizen to do a substitute military service there. He liked the work and the people, so he stayed. Van de Pol can tell all about the history of DIFFER’s experimental facilities.

Two expertises in one machine

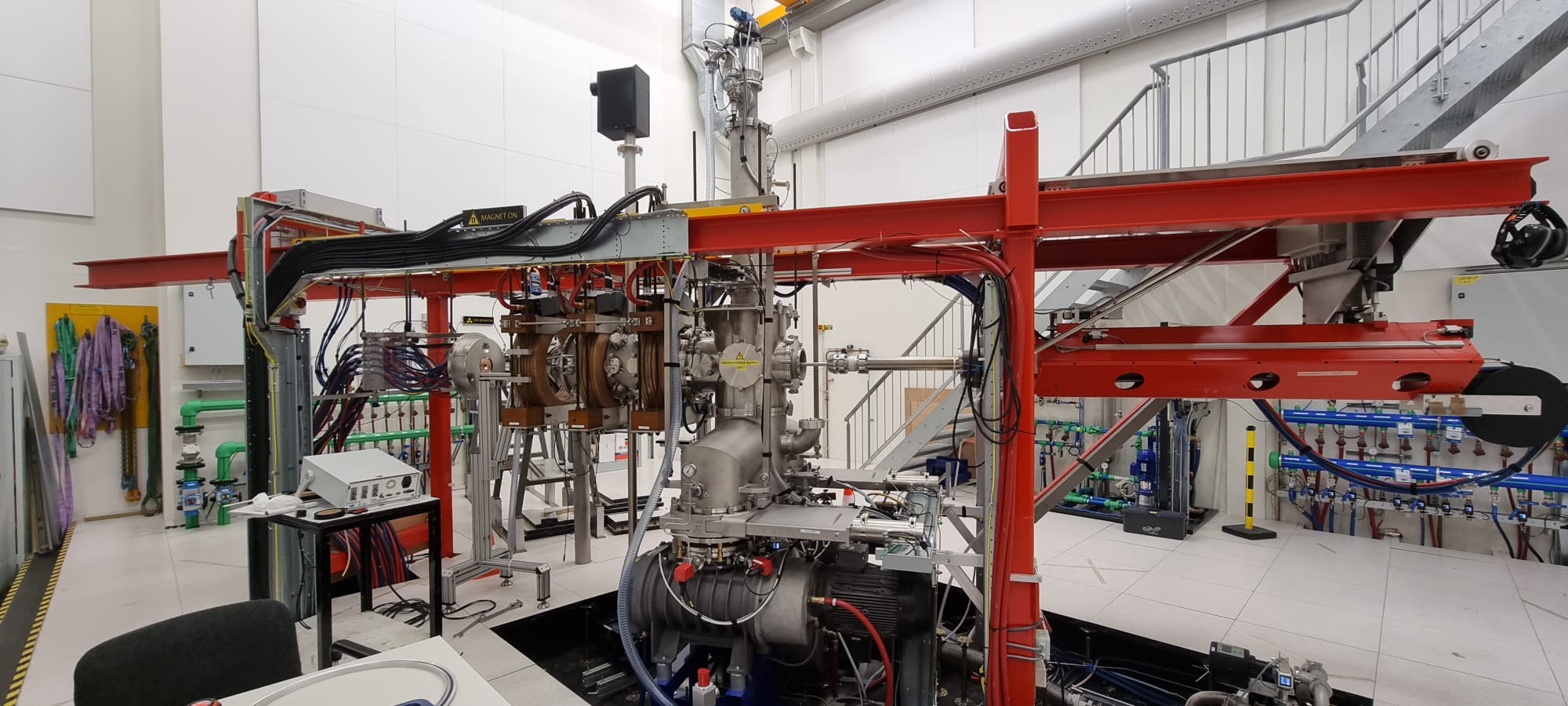

In the UPP linear plasma generator a source produces an ionized gas of free charged particles and electrons, a plasma. The plasma is injected into a vacuum vessel. Magnetic fields are used to confine the plasma into a beam that will interact with a piece of material, the target. The plasma-material interaction can alter the characteristics of the surface of the target material, which may have impact on the utilization of these materials in future nuclear fusion devices. UPP will be the first linear plasma generator to couple high flux plasma with an ion beam, to measure the plasma-material interaction processes during the plasma exposure, bringing two of DIFFER’s expertises together in one machine.

When did you start to work on the upgrade of UPP?

“In 2016, DIFFER obtained the linear plasma generator Plexus. We started to install this machine and make it operational again. After doing so, we discovered that this machine was not very user friendly. On top of that we discovered that the plasma parameters were not good enough to reach the goal that we had in mind, to do the experiments that we wanted to do with the machine. So we decided to do extensive modifications. Design work started in 2019.”

So that was a huge job. What are the modifications you made to UPP?

“Actually, apart from the red frame that you can see in the picture, we have changed almost every part of the machine. The vacuum vessel is new and we have improved the pump systems, and the cooling of the vessel and the plasma source. We have changed the mounting of the plasma source, so that we can simply and quickly exchange plasma sources if needed. We added new diagnostics, and improved the gas inlet system and the target motion control.”

Sounds like a complete makeover. What about the user friendliness of UPP now?

“Plexus had an old control and data acquisition system that we could not maintain, change or modify ourselves. You had to write down all the system settings data in notebooks. It was hard to find out later whether everything had been set up correctly. So we have completely renewed this system, both the hardware and the software. Now we have a user friendly control of the experiments with graphical user interfaces, in which you can see all the actuators and sensors, so it's easy to find out what you should do to get things operational and to see what the reaction of your system is. All the data are captured fully automatically in a database, and it is easy to retrieve all records and to do data analysis.”

Do users need a lot of expertise to work with UPP?

“The system can be controlled both in automatic mode where you only have to click start and the corresponding part starts automatically in a pre-programmed way. Or you can use the expert mode, where every part can be switched on and off individually. So we think we have created a system that can be easily operated. We hope that in the near future students can work with this machine by themselves with only a minimal amount of support from the Fusion Facilities and Instrumentation group, together with the operator for the ion beam that will be connected to this machine.”

Is there still work to be done?

Van der Pol laughs. “With a machine like this, the work is never done. An important next step is in the diagnostics: we want to to use the ion beam not only after, but also during the experiments. We hope to have this up and running early 2022.”

The UPP upgrade must have been team work. How many people have participated in it?

“The whole Fusion Facilities and Instrumentation group has worked on it. Also basically everybody from all DIFFER’s technical departments, so in total around twenty people, have contributed to the project.”

What was the most difficult thing you encountered during this project?

“All technicians work on multiple projects. Sometimes it was difficult to organize the work because not everyone always had enough time to devote to UPP.”

What was the best thing you have experienced during this project?

“The most beautiful moment is now. We start to see the results of our efforts , that is wonderful. I hope that there will soon be a time when we can all come together to celebrate our accomplishments.”

More information

Research group Fusion Facilities and Instrumentation

News item Successful first experiment with Upgraded Pilot-PSI

Go to the News page.