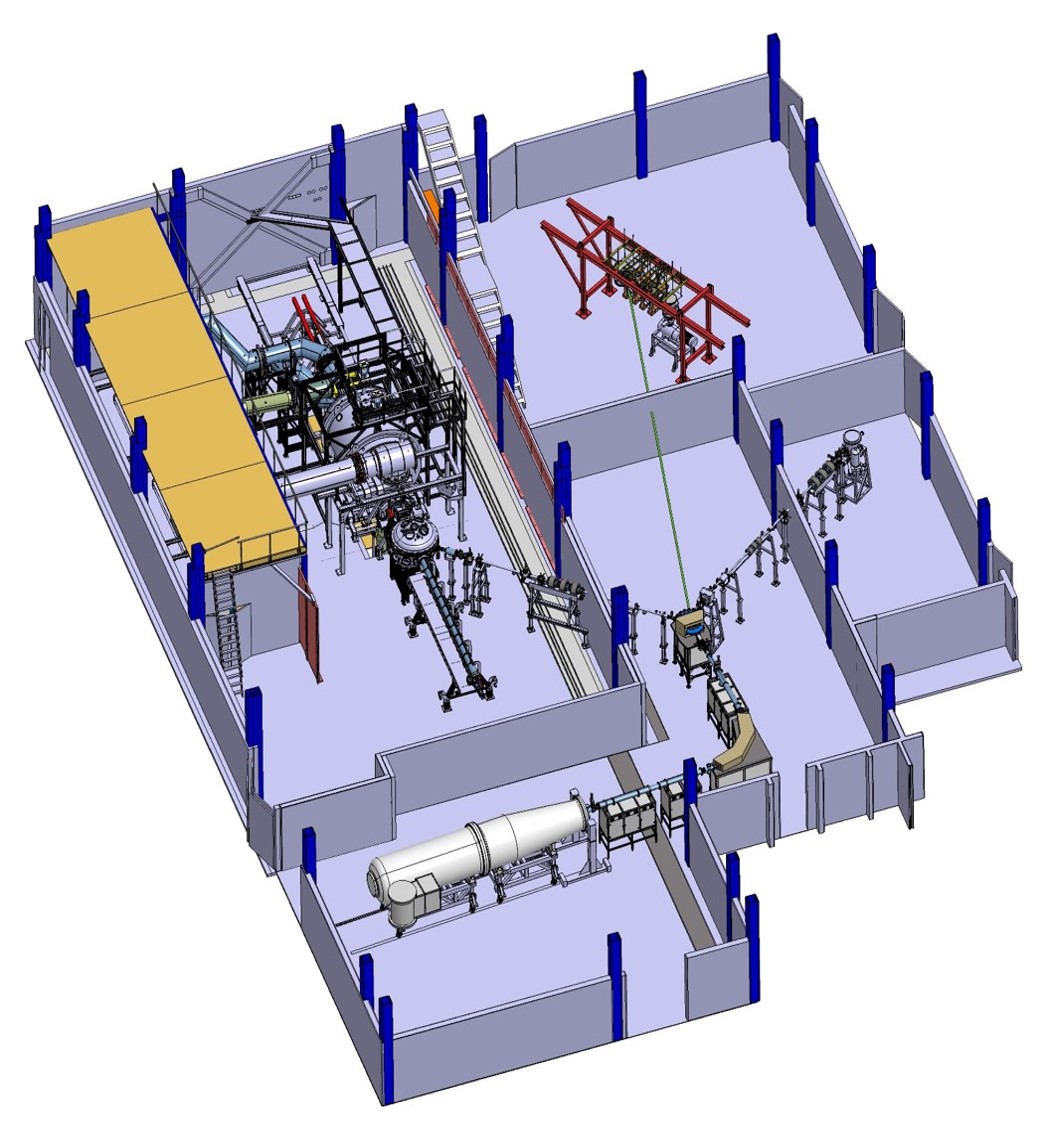

DIFFER has started the assembly of an upgraded version of its successful Pilot-PSI (Plasma Surface Interaction) project. By connecting the device with its powerful plasma source and steady state magnets to a beamline of the Ion Beam Facility, Pilot-PSI Upgrade will be able to deliver new insights in the real-time dynamics of how materials react to a plasma.

DIFFER. The Ion Beam Facility

(bottom) connects to both

Magnum-PSI (top left) and to

Pilot-PSI Upgrade (top right).

Connecting experiments

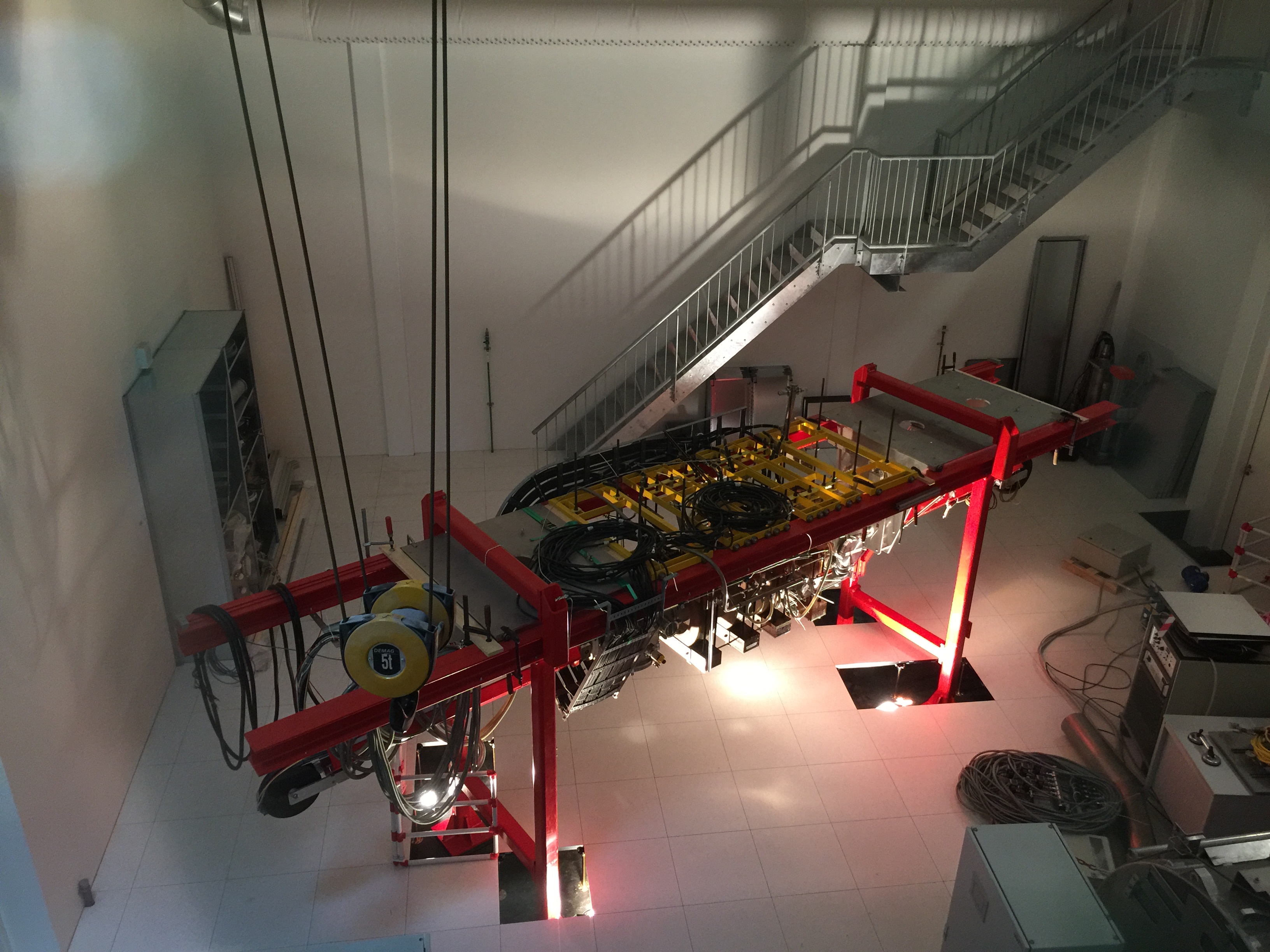

"Our ambition is to go live by the end of 2017", says Dennis Ronden. "We are now in the phase of starting up the assembly of Pilot-PSI Upgrade. A very challenging job because not all components of Pilot-PSI could be moved from the former location. The magnet coils were too delicate to be shipped. Luckily we could acquire new coils from the TU/e, together with a more suitable vacuum vessel. We received great help from the TU/e in moving the equipment and using it as basis for Pilot PSI Upgrade. The whole exercise also enabled us to make excellent connections to our partner at this campus."

Pilot-PSI Upgrade will be connected to the existing Ion Beam Facility (IBF). For optimum diagnostic results, the ion beam needs to enter the vacuum vessel of Pilot-PSI Upgrade under an oblique angle and fit between the coils that surround the vessel. "It is now roughly placed in the right position and orientation," explains Ronden. "Once the detailed design of the ion beam interface is made and the new components of Pilot-PSI Upgrade get installed, the device can be aligned further and connected."

Real-time insights for fusion and beyond

Pilot-PSI Upgrade will deliver new insights in the dynamics of how materials evolve under the bombardment of particles and heat in a dense plasma. It is the second linear plasma device at DIFFER and while it offers a lower magnetic field and a less intense plasma, its strong suit is allowing ion beam analysis of how materials change during exposure to the plasma. The main facility Magnum-PSI can expose larger samples, but can only perform ion beam analysis before and after plasma exposure.

Dennis Ronden, the project leader of Pilot-PSI Upgrade: "We have never seen what happens during plasma exposure. The amount of plasma impacting the target is so large that we expect to really change the structure of the material. What dynamic processes are involved? This is really unknown physics."

Research will not necessarily limit itself to the study of materials for fusion reactors. "The processes that change the material and / or its surface might be interesting from a manufacturing perspective as well. Studies were done on Pilot in the past that lead to the discovery of new ways to create surface structures that may find application for instance in surface chemistry. This line of research will likely be continued in Pilot-PSI Upgrade, although this is up to the scientists involved."

Building up Pilot-PSI Upgrade

There is a long way yet to go, before Pilot-PSI Upgrade is ready to start the first experiments. The magnetic coils and their power supplies will have to be replaced. Ronden: "The old Pilot-PSI coils were oil cooled and required a lot of power to generate the required magnetic field, while these are water cooled and are optimized for longer operation at a lower magnetic field, requiring less power. In fact, these coils can operate in steady-state without the risk of overheating."

Components that will also be upgraded are the vacuum pumps. The current ones are not powerful enough to meet the requirements of the new set-up. Ronden: "We want to lower the vacuum pressure we could reach in the Pilot before the move by a factor of 2. To achieve this, we’ll need to install larger pumps than we currently have, plus they’ll need to be placed directly below the device, to maximize effective pumping speed. This will demand some level of sound-proofing as such a size pump will easily produce noise in excess of 80 dB, while we need to be able to work in this room. It’s not just us; there are other projects scheduled to be placed in this room. We need to take that all into account while designing this experiment. We all want to be able to do our jobs without safety hazards and without bothering each other." The goal is to have the machine ready to start the scientific program in 2018.

Go to the News page.