A Dutch consortium, led by national energy research institute DIFFER, will receive 4.7 million euros from NWO to build a facility that makes controlled layers of material. Through this facility, science and industry can explore materials for new catalysts and batteries. In doing so, they will accelerate the energy transition, helping to move society forward. The facility, globally unique, can produce small and large thin films which is key to scaling up to industrial use. The facility also incorporates many built in diagnostic tools to analyse the films on-the-spot.

To conquer the energy problem, researchers are searching for new materials, for example, for solar panels, catalysts that help produce hydrogen and batteries that store energy. Often, such materials consist of stacked layers of thin films which in combination have unique and useful properties.

Until now, there existed a gap between small scale materials research at research institutes and industrial production of thin films at companies. This is partly because research institutes often make thin film samples of a few millimetres or at most a few centimetres in diameter. These are difficult to test which prevents companies from further developing the material and making it market-ready.

Pulsed Laser Deposition lab

The new facility, the Pulsed Laser Deposition lab, allows research institutes and companies to make thin film samples up to ten centimetres in diameter. In addition, the device can stack layers. Moreover, researchers can already perform many measurements in the device itself. This provides faster and more accurate results. The facility will be available to researchers at universities and institutes and to companies wanting to test commercial applications.

"There is no equivalent facility in the world," says Anja Bieberle of the Dutch Institute for Fundamental Energy Research, DIFFER. Bieberle leads the consortium that will set up the facility at the premises of DIFFER in Eindhoven. "The facility lends itself to fundamental research and to the next, essential step, the actual implementation."

Stainless steel spheres under vacuum

The core of the facility is a device made of three stainless steel spheres connected under vacuum via pipes and tubes. The entire unit is about four metres long. Behind the spheres are eight different types of analytical equipment. There is also a loading chamber to insert new materials as cleanly as possible, without disturbing the vacuum.

Text continues below image.

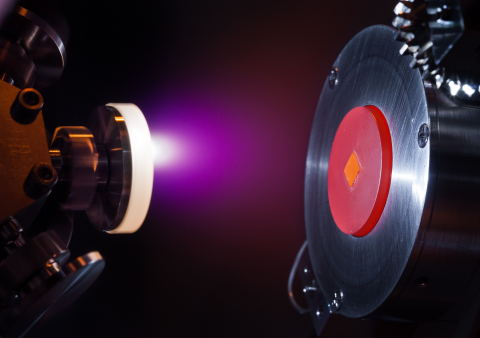

The central technique of the new Pulsed Laser Deposition lab is pulsed laser deposition. In this process, a laser beam (not shown) shoots pieces of material away from a pellet (left, white). The material evaporates as a plasma cloud (purple) and lands on a substrate (right, red). There it forms a layer one or a few atoms thick. (c) Adam Andersen Læssøe, CC BY-SA 4.0, via Wikimedia Commons [high resolution, portrait]

Consortium

The consortium operates under the name PLD4Energy. DIFFER is the main-applicant. Co-applicant University of Twente, together with DIFFER, designs the facility. Co-applicant Eindhoven University of Technology provides specific analytical equipment. Partners are Leiden University, Delft University of Technology, University of Groningen, Utrecht University and TNO.

Budget

The budget for the new facility comes from NWO's grant programme Research Infrastructure: national consortia. NWO will pay 4.7 million euros. The consortium will add 1.6 million euros to that. At the same time six other consortia will receive funding.

About DIFFER

DIFFER, the Dutch Institute for Fundamental Energy Research, conducts leading fundamental research in the fields of fusion energy and solar fuels. The institute works in close partnership with academia and industry. DIFFER (www.differ.nl) is based in Eindhoven and is part of the institutes organisation of NWO.

Dutch original news item: https://www.differ.nl/differ-ontwikkelt-onderzoeksfaciliteit-voor-energietransitie

Go to the News page.