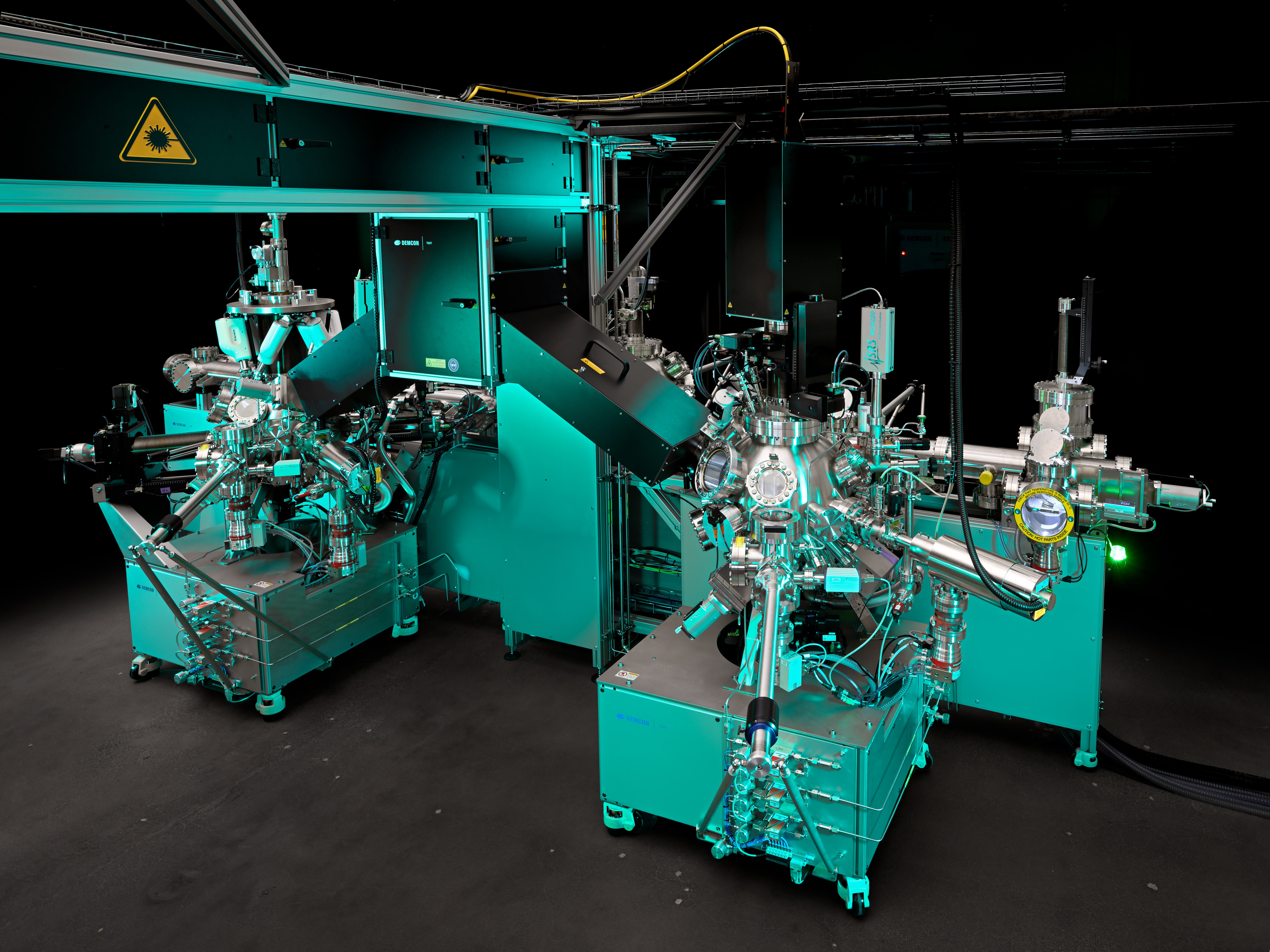

At DIFFER we have designed and build the thin film deposition and characterization facility PLD4Energy. The main facility consists of a linear transfer line that connects two chambers for pulsed laser deposition (1 inch and 4 inch deposition area), one chamber for sputtering (up to 4 inch), and an X-ray photoelectron spectroscope.

The PLD chambers are surrounded by multiple in-situ characterization techniques. They range from standard tools, such as reflection high-energy electron diffraction (RHEED), optical emission spectroscopy (OES), spectroscopic ellipsometry, and multi-beam optical sensor, to new developments based on X-rays and spectroscopical methods.

The facility is specially designed for 4 inch capability (both wafers as well as samples of diverse size and shape), materials screening, particle reduction, and component development (in-situ masking possibilities). Next to the main facility, several ex-situ diagnostics are available for process control and materials characterization.

Visit DIFFER's virtual tour to see the Pulsed Laser Deposition facility in panorama view.