Particle injection is fundamental for tokamak operation: many plasma parameters can be influenced by plasma fuelling and impurity seeding . The injection of particles is executed by a gas delivery system containing numerous valves located throughout the tokamak, which make near-localized gas deposition possible. This near-localized deposition of gas provides opportunities in many tokamak control areas, such as detachment, density and radiation control. Research efforts in the control of these processes, however, have required increased trajectory-tracking capabilities of the gas valve, where its internal dynamics occasionally proved to be problematic.

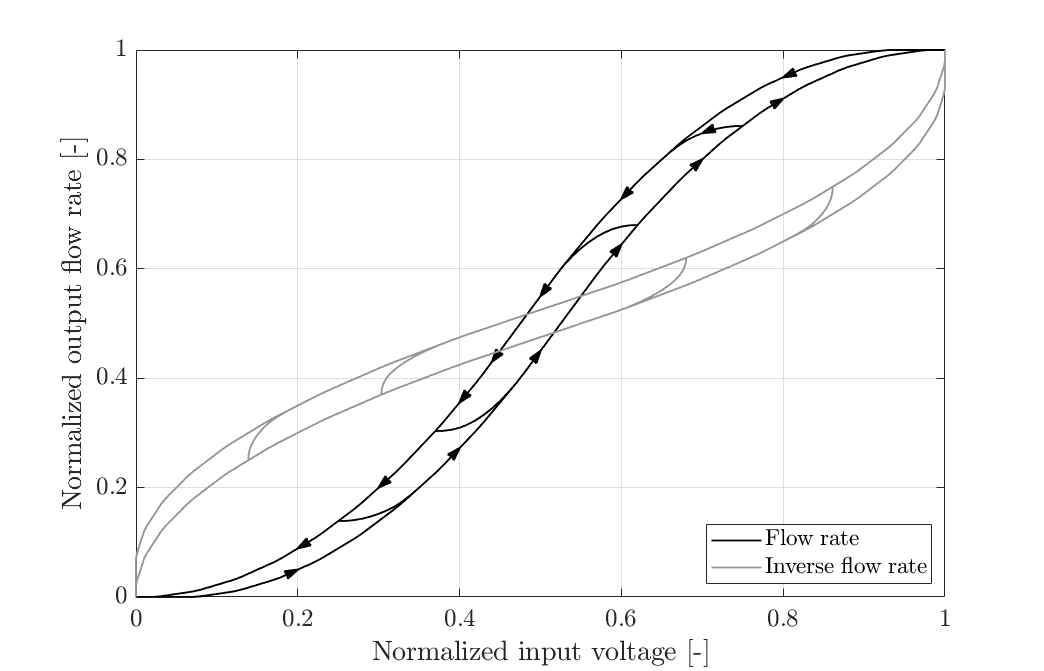

In a recent experiment of the Energy Systems and Control group in which the plasma detachment dynamics were identified, the limiting factor was the gas valve exhibiting an insufficiently high bandwidth and nonlinear behavior in its piezoelectric actuator. For this reason, the Energy Systems and Control group is focusing on the characterization of the nonlinear valve dynamics (see Figure), and the linearization and control thereof. To ensure convenient characterization of the individual dynamics of the many valves on a tokamak, an adaptive nonlinearity compensation (see Figure) and system identification scheme is developed.

Figure: Typical nonlinear behavior in a gas valve of a fusion reactor. Once this nonlinear behavior is identified (black), it can be eliminated from the system with its inverse (gray).

Back to Research.