Future fusion power plants will need wall materials that do not crack or melt under the intense heat inside. In his PhD research, mechanical engineer Jos Scholte (TU/e and DIFFER) studied if liquid metals can act as a protective layer for the exhaust wall. He successfully defended his PhD thesis on 3 June 2025.

Fusion reactor divertors must endure heat loads of tens of megawatts per square meter for extended periods—like sitting under a rocket exhaust. Can a cover layer of liquid metal protect the materials underneath? Such a layer would not only be immune to cracking, it would also create a cooling vapor cloud above it for even more protection against the intense heat.

Nine shots before shutdown

Liquid metals also have peculiarities that need to be investigated, like the possibility of splashing, launching disrupting droplets or absorbing precious fuel. With dual Master's degrees in mechanical engineering and nuclear fusion, Scholte designed a holder for liquid tin and tested it in the German tokamak ASDEX-Upgrade at the Max Planck Institute for Plasma Physics IPP near Munich.

To verify that his design would work as planned, Scholte first ran tests at DIFFER's linear plasma generator Magnum-PSI and in the GLADIS facility at IPP. That cleared the way for a full day of dedicated experiments in ASDEX-Upgrade, just before the tokamak shut down for a two-year upgrade. Those nine shots produced food for thought that drove the entire PhD thesis.

Cooling Power

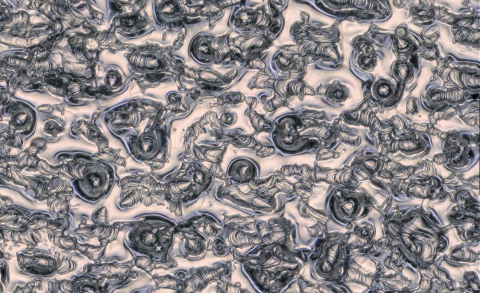

Scholte's results are a mixed message.On the one side, his metal sponge full of liquid tin generated a noticeable cooling effect. That is not automatically good news, because the fusion fuel should not be cooled to below fusion temperatures. Inspection photos also showed liquid tin flowing out of the sponge structure. One droplet of tin even launched itself to a neighboring sector of the tokamak, leaving a 0.5 cm streak.

"Launching droplets of cooling metal through the core plasma is obviously not what you want", says Scholte. Instead of turning to engineering solutions to screen droplets, he decided to focus on clearing up which mechanism causes liquid metal to migrate inside a fusion reactor.

Champagne formula

In the scientific literature and at conferences, Scholte encountered multiple possible explanations for why liquid tin creates droplets. "You hear these five explanations being repeated time and again. I wanted to find out if we could weed those down."

In a dedicated paper, Scholte was able to rule out boiling, electromagnetic forces, instabilities, and chemical reactions by comparing them to insights from previous experiments. Only one explanation remained: the liquid metal becoming oversaturated with hydrogen from the plasma fuel, until it starts to bubble.

"A bit like the CO2 dissolved in champagne, which starts to bubble out when the pressure drops", explains the newly minted doctor, who applied formulas that normally describe bubbly wine to his liquid metals.

Next Steps

Scholte hopes the community will be able to use the insights from his liquid tin experiments to design future divertors. He also hopes to see research on other liquid metals, like gadolinium.

Asked about his own work, Scholte explains his next project: building a 'digital twin' simulation of the divertor materials in a fusion reactor. "You could use that to assess limits and predict maintenance needs." One way or another, Scholte keeps an eye on the well-being of divertor materials.

Author: Gieljan de Vries

Go to the News page.