Within the Plasma Material Interactions group we concentrate on three main research areas by exploiting our globally unique linear plasma devices and other in-house equipment.

1. Solving plasma material interaction questions for ITER

How much fuel will be trapped in the divertor wall over long timescales? Is there a synergistic effect of transient plasma loading with the steady-state plasma flux? What sort of shaping should be applied to the ITER monoblocks in order to avoid edge melting during transients? These are all questions we try to tackle.

Test driving the ITER divertor

The ITER divertor undergoes extreme conditions at the strikepoints which are very challenging for materials: heat loads of up to 20 MW m-2, similar to the heat flux density at the surface of the Sun, and particle fluxes so high that an ion hits each atom on the surface around once every microsecond. To deal with this the divertor wall is constructed of high pressure water cooling pipes with a precision-aligned tungsten armour. Until now testing of these armoured components under loading conditions had been limited to the equivalent of a few plasma discharges in ITER. With the development and installation of the superconducting magnet at Magnum-PSI in 2016, this offered the opportunity for the first time to start approaching ITER lifetime loading conditions. To test this we used a mock-up of part of the tungsten armour and exposed it to a variety of different conditions expected during ITER's operational lifetime. The most extreme conditions were the equivalent of one year of full power ITER operation. This was achieved in 20 hours in Magnum-PSI, and is an increase of about a factor 50 compared to previous work. The headline results were that the blocks performed well, and may be expected to successfully withstand similar conditions in ITER.

Do you want to know more?

T W Morgan et al 2020 Phys. Scr. 2020 014065

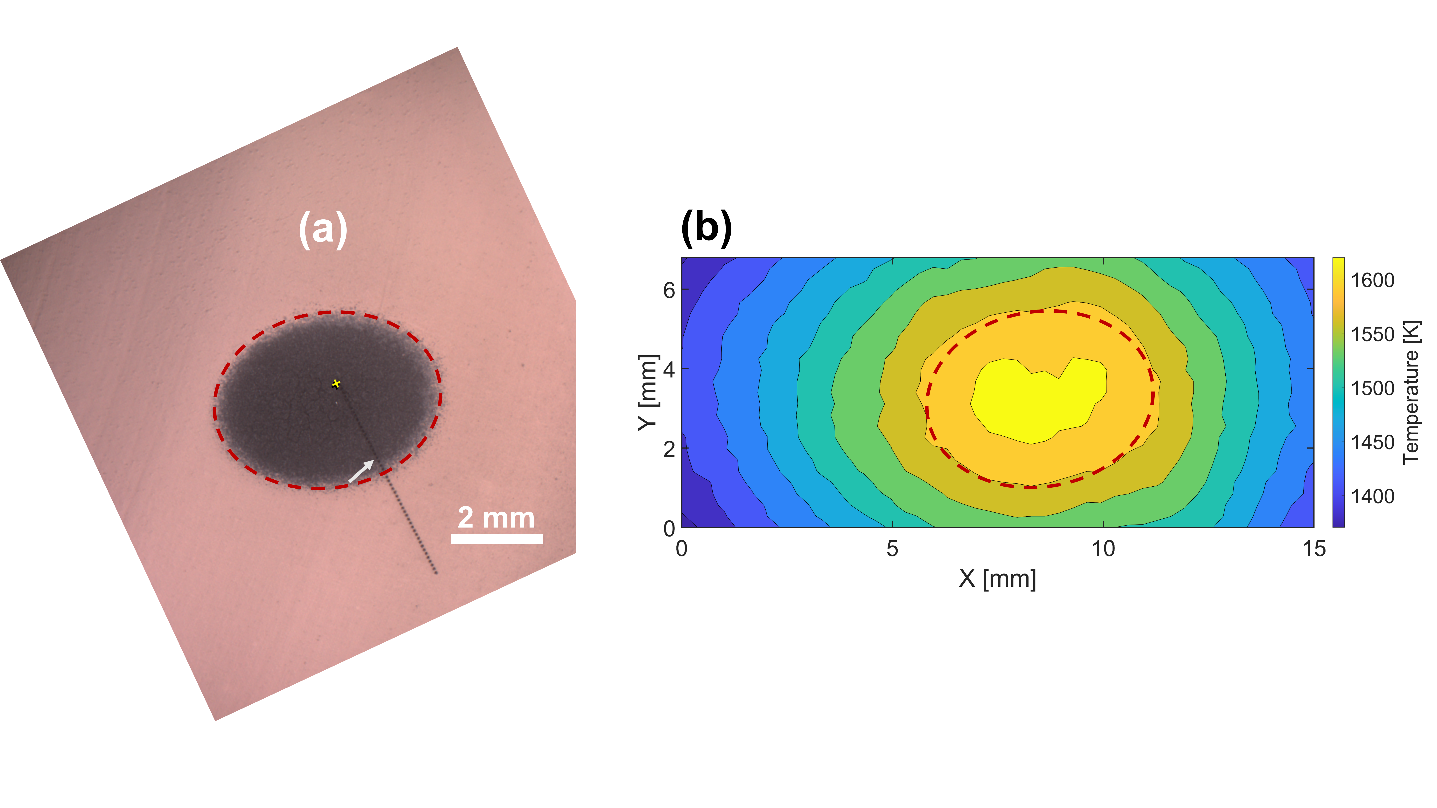

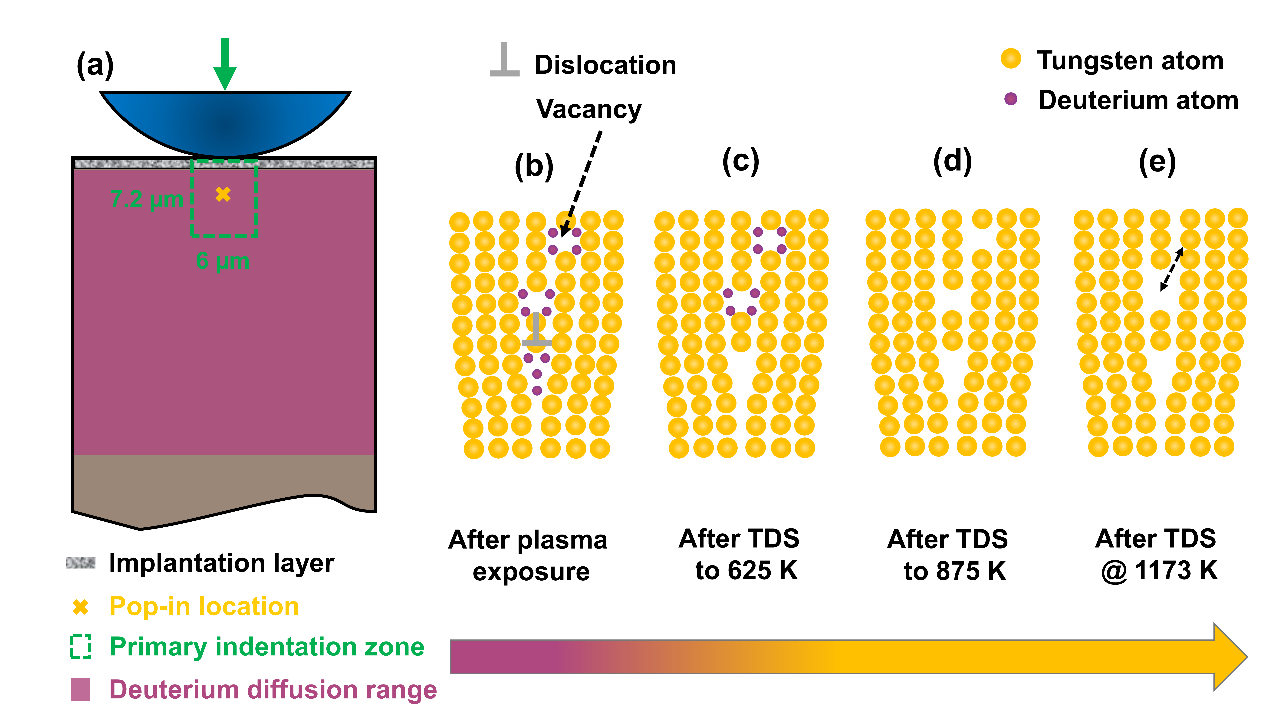

Understanding the influence of hydrogen on surface cracking

Evaluating the long-term thermo-mechanical performance of the tungsten divertor for ITER is currently among the key research topics in the nuclear fusion community. Here we approach this research question at DIFFER using the flagship linear plasma machine Magnum-PSI and various post-mortem characterization techniques. Edge Localized Modes (ELMs) are periodic bursts of energy that erupt from the edge of the confined plasma in high-performance discharges in tokamaks. When they travel down the magnetic field lines into the divertor their impact on the tungsten wall surface stresses the material and can lead to cracking. We exposed tungsten samples to high flux hydrogen plasma while simultaneously simulating ELMs using a high-power laser. At the macroscale we correlated the fracture behavior of tungsten with its local heat flux where we found a rather small crack initiation threshold. This implies that surface cracking is inevitable in ITER even for very small ELMs. To probe the underlying mechanisms, we combined nanoindentation and thermal desorption spectroscopy and revealed nano-scale interaction between hydrogen and dislocations, the primary carriers of plasticity in tungsten. The pinning of dislocations by hydrogen plasma exposure could make tungsten brittle, therefore prone to fracture.

Do you want to know more?

Y. Li et al 2020 Nucl. Fusion 60 086015

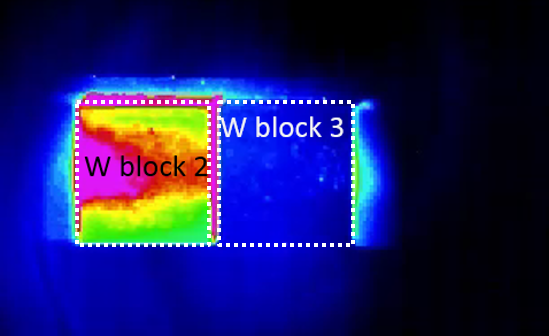

How do misaligned edges affect power deposition on the ITER divertor monoblocks?

The ITER divertor is constructed of hundreds of thousands on tungsten armour blocks (monoblocks), mounted in rows on a copper cooling pipe. These have to be aligned very precisely with respect to one another to a precision of less than 0.3 mm because the plasma intersects the surface at an extremely low angle of around 3°. This means any protruding block edge will be strongly overheated by the parallel heat load of the plasma, likely causing recrystallization and potentially melting of the edge. A key question for ITER at the end of the design phase of the divertor was therefore whether each of these leading edges should be shadowed by shaping it or not. To take this step is an extra expense and reduces the effective area of the divertor which intercepts the plasma, and the question is complicated by the fact that the ions and electrons do not travel in straight lines but are actually making Larmor-orbit motions, i.e. travelling in spirals along the field lines. This motion can help to smear the parallel heat load out so it is not so severe compared to if everything is treated as travelling in straight lines (the so-called optical approximation). To investigate what was the best solution, we put a set of blocks under a range of small incidence angles (4-8°) and range of misalignments (0-1.2 mm) and exposed them to high flux plasma in Magnum-PSI. We then compared our measurements to Finite Element Method (FEM) modelling. This showed that in our case the optical approximation and the Larmor smoothing effect were not significantly different. As part of a larger collaboration with a large number of tokamaks and plasma groups around the world we helped ITER to decide that shaping of the ITER was a good idea, and they implemented in the final design of the divertor before it went into production.

Do you want to know more?

T.W. Morgan et al 2017 Nucl. Fusion 57 126025

R.A. Pitts et al. 2017 Nucl. Mater. Energy 12 60-74

2. Developing divertor material solutions for DEMO

Pure tungsten blocks will be used as the armour material for the ITER divertor, but they may not be suitable for the first generation fusion reactor DEMO and its successors. Higher neutron loading and longer duty cycles mean we may need more advanced solutions. We investigate advanced tungsten grades, alternative designs like heat pipes as well as using liquid metals as a the plasma facing material instead.

Using liquid metals as a self-shielding plasma facing material via vapour shielding.

Liquid metals have several advantages over solid plasma facing components (PFCs): any eroded material can be replaced by new material flowing in, they are capable of cooling other than by conduction, and that the liquid is not so susceptible to damage from neutrons. For these reasons we study the performance of liquid metals as a PFC for future fusion reactors. The main candidate liquid metals are lithium or tin. We found that when the surface temperature increases under intense plasma loading, a regime is reached where the high vapour pressure balances the incoming plasma pressure. This results in a reduced heat load to the surface as the vapour cools the plasma and increases radiation. This type of self-regulatory behaviour can protect the wall from damage under off-normal events, making the plasma more robust. It is even possible to conceive of operating in this regime in steady-state to essentially control and extinguish the heat load as it enters the divertor, eliminating the problem of wall damage, using a so-called "vapour-box" divertor. We are also exploring how this can be designed and engineered for a future reactor.

Do you want to know more?

G.G. van Eden et al. Phys. Rev. Lett. 116 (2016) 135002

G.G. van Eden et al. Nat. Commun. 8 (2017) 192

Liquid metal heat shield design for the European DEMO reactor

The next generation fusion reactor, DEMO, will deliver electricity to the grid. Construction for the European DEMO will be started halfway this century by the European organization EUROfusion. However, a main obstacle remains that must be overcome: Extreme loads on the wall of the reactor chamber (cyclic loads on the order of 10MW/m2, millisecond transients up to 80 GW/m2, and the highest neutron fluxes in any man made machine). Fortunately, liquid metal heat shields have greatly increased resilience against these loads, and may enable DEMO. Even more so, future developments may allow for further optimization of the reactor as a whole.

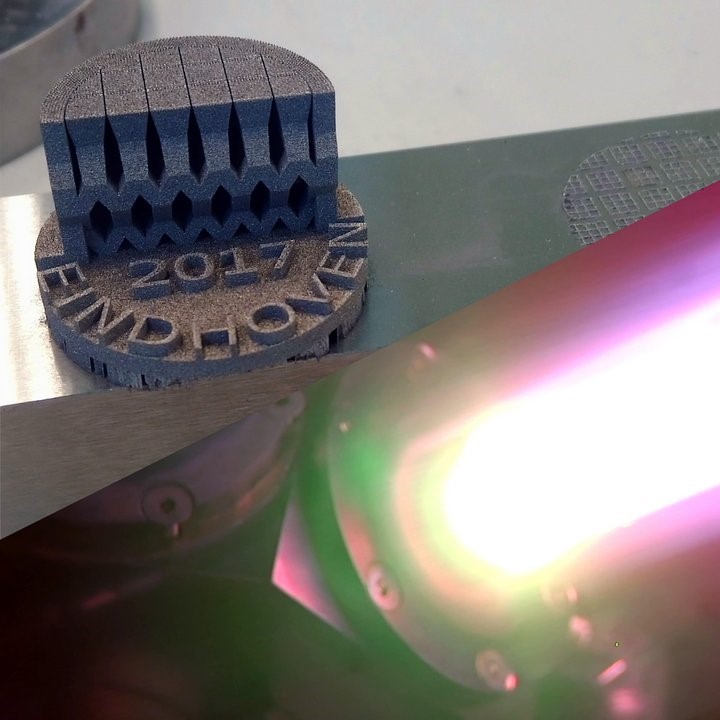

Our current activity focusses on the development of a realistic mock-up design, which can ultimately be tested at DIFFER. This includes conceptual design work, detailed design of a mock-up in collaboration with industry, and experimental testing at various facilities in Europe besides DIFFER. This work is carried out in close collaboration with EUROfusion. Earlier work at DIFFER, in collaboration with the Eindhoven University of Technology (TU/e), includes: Detailed studies of the interaction between fusion plasmas and liquid metals; and the development of 3D-printed tungsten porous structures which are optimized to hold the liquid metals, see the figure below. This work forms the basis upon which the design for DEMO is based.

Do you want to know more?

P. Rindt et al 2018 Nucl. Fusion 58 104002

P. Rindt et al 2019 Nucl. Fusion 59 056003

P. Rindt et al 2019 Nucl. Fusion 59 054001

3. Knowledge exploitation and valorization

Our linear plasma devices create conditions where the rate of particles hitting the material is extremely high, and the path lengths between collisions extremely small, so that the material can be pushed out of equilibrium. We can use our knowledge to explore questions relevant for industry, or use our unique conditions to explore the strange morphology changes these create and see how we can use them in catalysts, batteries or solar cells.

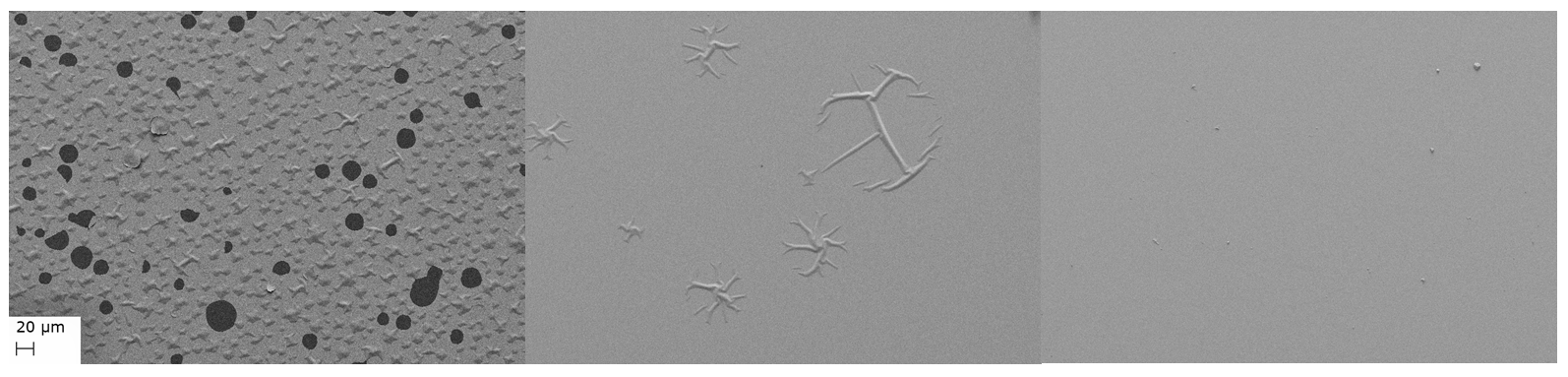

Understanding blistering in EUV lithography

Blister formation in thin films have recently been an emerging research subject in relation to vacuum ultraviolet (VUV) mirrors in lithography tools and nuclear fusion reactors. Both devices contain hydrogen-isotope plasmas, and VUV mirrors are exposed to high-flux ions and radicals coming from the plasmas. Blister formation results from hydrogen atoms retained in the materials and could lead to delamination of thin films. We have focused on the effect of Sn on Ru-capped mirrors since they are the common materials used in lithography tools. We found a strong correlation between the blister density and the amount of Sn on the Ru-capped target surface. As shown below, the density of blisters increased with the amount of Sn on the target surface. This showed that Sn on the surface accelerates blister formation on the target. The result is qualitatively consistent with recent computational work also carried out in the group, showing the presence of Sn on Ru lowers the energy barrier for hydrogen to move from the surface to the sub-surface.

Want to know more?

C. Onwudinanti et al. Phys. Chem. Chem. Phys., 2020,22, 7935-7941

C. Onwudinanti et al. Nanomaterials 2019, 9, 129

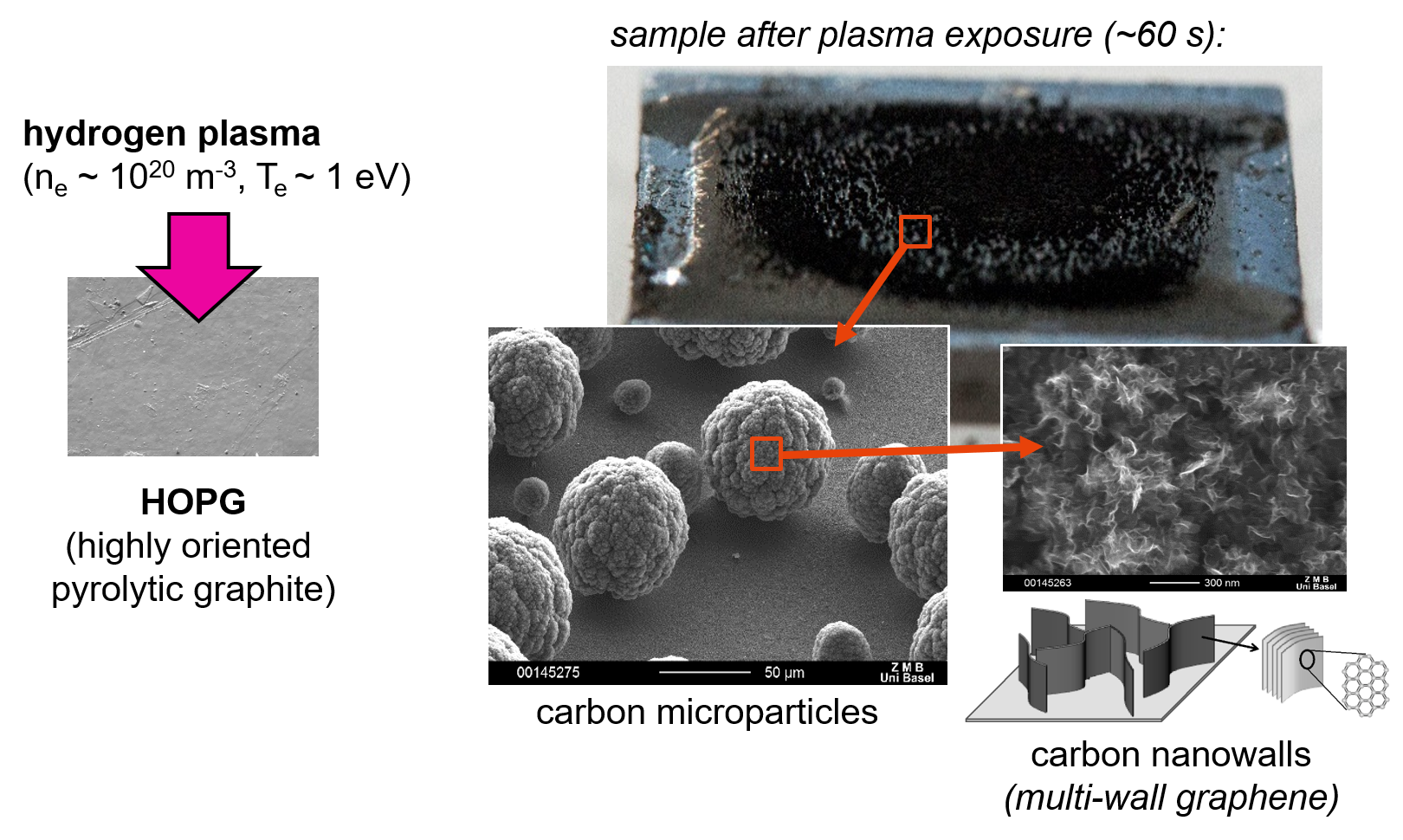

Fast nanostructured microparticle synthesis via high-flux plasma processing

Improved electrochemical performance can be achieved in energy storage systems such as Li-ion batteries and supercapacitors from porous carbon electrode materials whch have very large surface area due to meso and micropores. Graphene-based materials have been shown to have very good electrochemical performance, but typically require a complex multi-step process to be created. We were able to demonstrate a fast on-step process to produce nanostructured microparticles with good pore structure using high flux plasma processing of highly orientated pyrolytic graphite surfaces. Porous microparticles were found to spontaneously grow in only 1 minute under the loading conditions. TEM analysis shows that they are constructed of carbon nano-onions and carbon nanowalls with very high surface area.

Want to know more?

D.U.B. Aussems et al. Carbon 124 (2017) 403-414

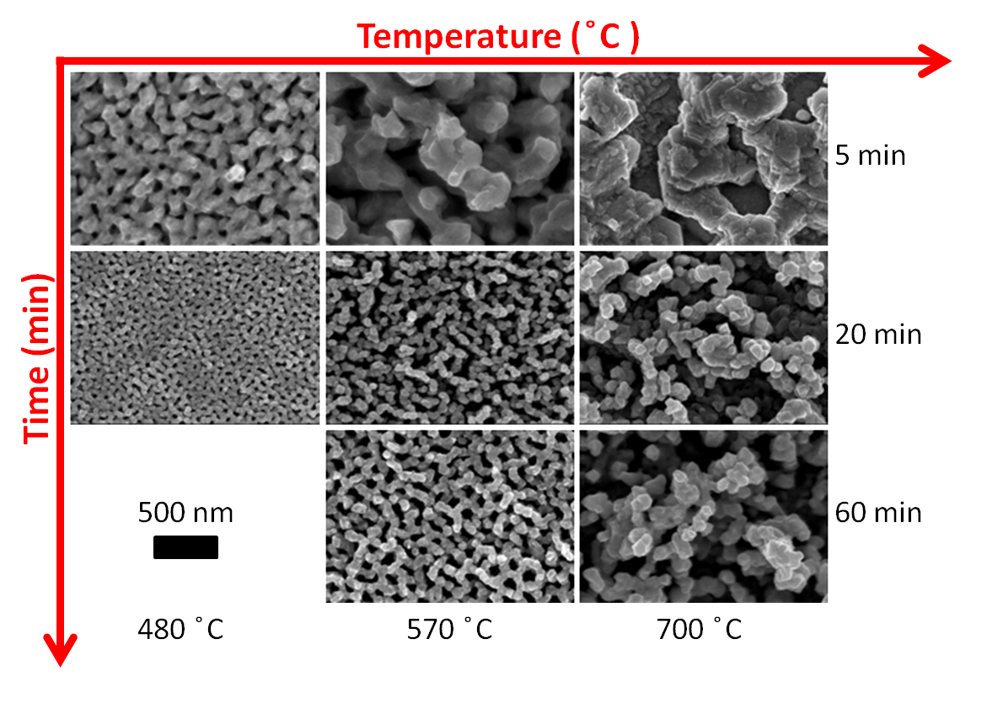

Nanostructuring photocatalysts with helium bombardment

To convert solar energy to hydrogen requires catalytic surfaces with large surface area. Using dense helium plasma bubbles form in metal surfaces which can then form foamy nanostructured surfaces. Following oxidation these can act as photocatalysts for water splitting. We have demonstrated that we can precisely control and tune the nanostructure properties as a function of plasma exposure time and temperature, and that the metal oxides work as photocatalysts for these applications.

Do you want to know more

De Respinis et al. ACS Appl. Mater. Interfaces, 2013, 5 (15), pp 7621–7625

Collaboration makes us stronger

As well as our own in-house research we work closely with dozens of researchers and research groups around the world on many additional topics. We work together to plan and execute experiments in our linear devices and collaborate in interpreting the results, maximising the effectiveness of our research. If you have an experimental proposal please fill in the web form.